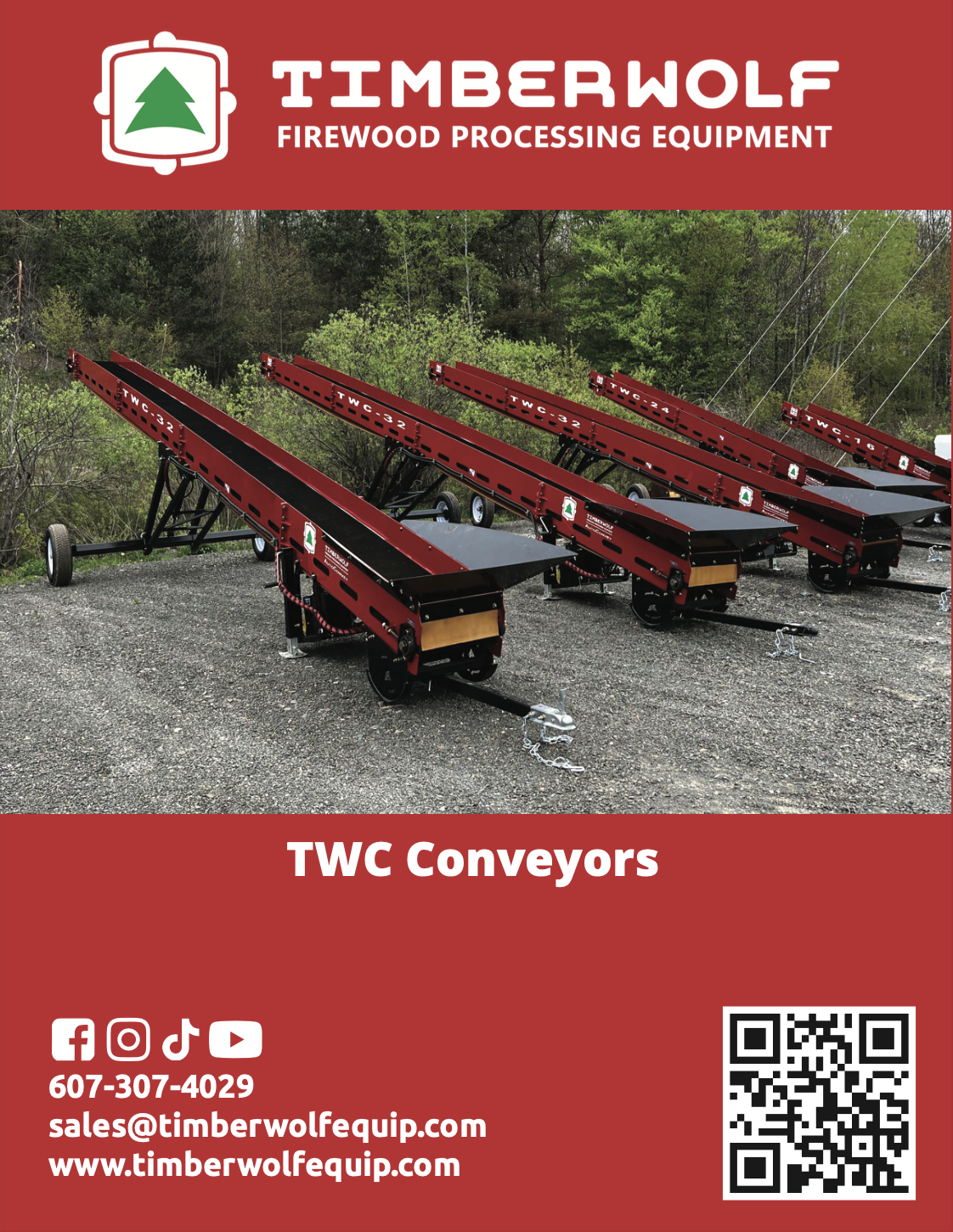

FIREWOOD CONVEYORS

-

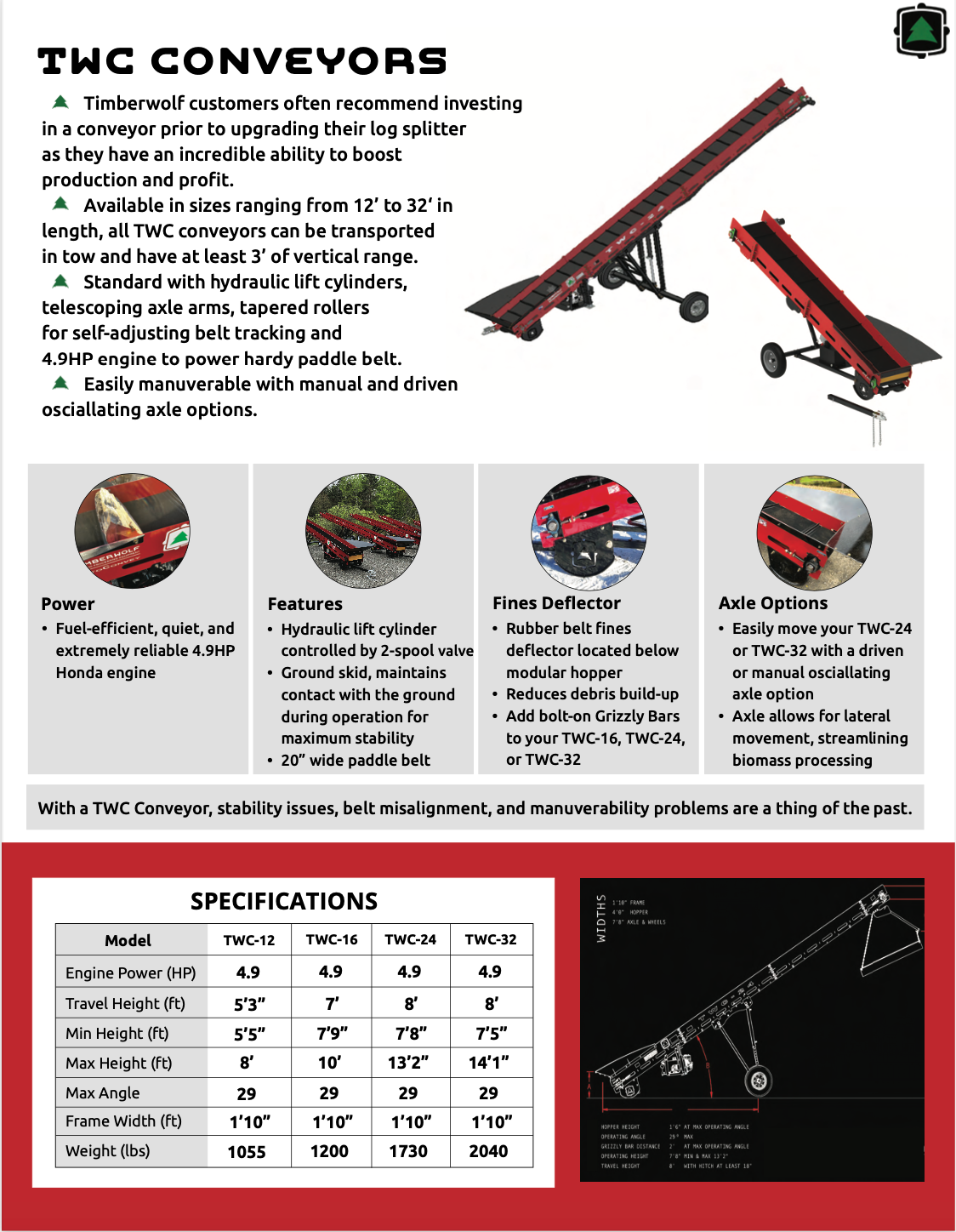

TWC-12

Regular price $6,000.00 USDRegular priceUnit price / perThe TWC-12 has a 12’ long frame capable of operating as high as 8’ in the air and as low as 5’5”. The hydraulic lift cylinder makes height adjustments safe and easy, plus, the TWC-12's tapered rollers self-align so you don't have to stop your job and realign the conveyor.

-

TWC-16

Regular price From $8,000.00 USDRegular priceUnit price / perThe TWC-16 firewood conveyor has a 16' reach and can operate as high as 10' in the air. The wood conveyor comes standard with self-aligning tapered rollers for belt tracking and a hydraulic lift cylinder for height adjustments.

-

TWC-24

Regular price From $11,000.00 USDRegular priceUnit price / perThe TWC-24 conveyor can operate as high as 13’2” in the air and as low as 7’8”, with a 24’ long frame. The wood conveyor can be optionally equipped with Grizzly Bars to filter fine materials from offloaded logs and/or a manual or driven oscillating axle to move the conveyor with ease.

-

TWC-32

Regular price From $12,000.00 USDRegular priceUnit price / perWeighing 2,040 pounds with a frame length of 32’, the TWC-32 is Timberwolf's largest commercial wood conveyor. The TWC-32 has max operating height of 14'1" and a minimum operating height of 7'5". Grizzly Bars and/or a manual or driven oscillating axle can be optionally equipped to the commercial wood conveyor.

Featured Product: TWC-12 Conveyor

Firewood Conveyors For Sale

Timberwolf firewood conveyors are designed with a funnel-like hopper for easy transportation from the log splitter to the firewood elevator, tapered rollers for self-correcting belt tracking, and a hydraulic lift cylinder for effortless height adjustments.

Timberwolf currently manufactures firewood conveyors that range in length from 12' to 32', namely the TWC-12, TWC-16, TWC-24, and TWC-32.

Increase Your Firewood Production

Every firewood professional knows the importance of a reliable and easy-to-use firewood elevator. They boost production, make transportation simple, and take some of the "work" out of firewood production.

Each Timberwolf wood conveyor is equipped with tapered rollers that self-adjust for correct belt tracking, a hydraulic lift cylinder for height adjustments, and a ground skid for guaranteed stability on level ground.

Simplify your firewood processing operation with a TWC Series firewood conveyor.

Offload Clean Firewood

Timberwolf's Grizzly Bars - shown here - bolt onto the offloading end of the wood elevator. The tapered bars allow fine materials to fall to the ground while slowing the descent of split logs onto a truck bed.

Grizzly Bars can be attached to all TWC conveyors beside the TWC-12.

This simple firewood processing accessory offloads wood ready to be packaged, sold, and profited off of.

Conveyor With an Oscillating Axle

With the TWC-24 and TWC-32, operators can move the firewood conveyor side-to-side, away from large piles of firewood, in just a couple of seconds. The log conveyor is capable of such movement because of the oscillating axle the firewood machine uses.

While standard axles face forward, the conveyor’s oscillating axle faces inward, allowing the machine to move side-to-side. This movement can be achieved by simply pushing the wood elevator to one side or the other, or an optional drive motor can be equipped and controlled via two single-spool valves.

This feature is only applicable to TWC-24 and TWC-32 firewood conveyors.