Timberwolf Firewood Processing Equipment

TWC-32

TWC-32

Wood Conveyor

Couldn't load pickup availability

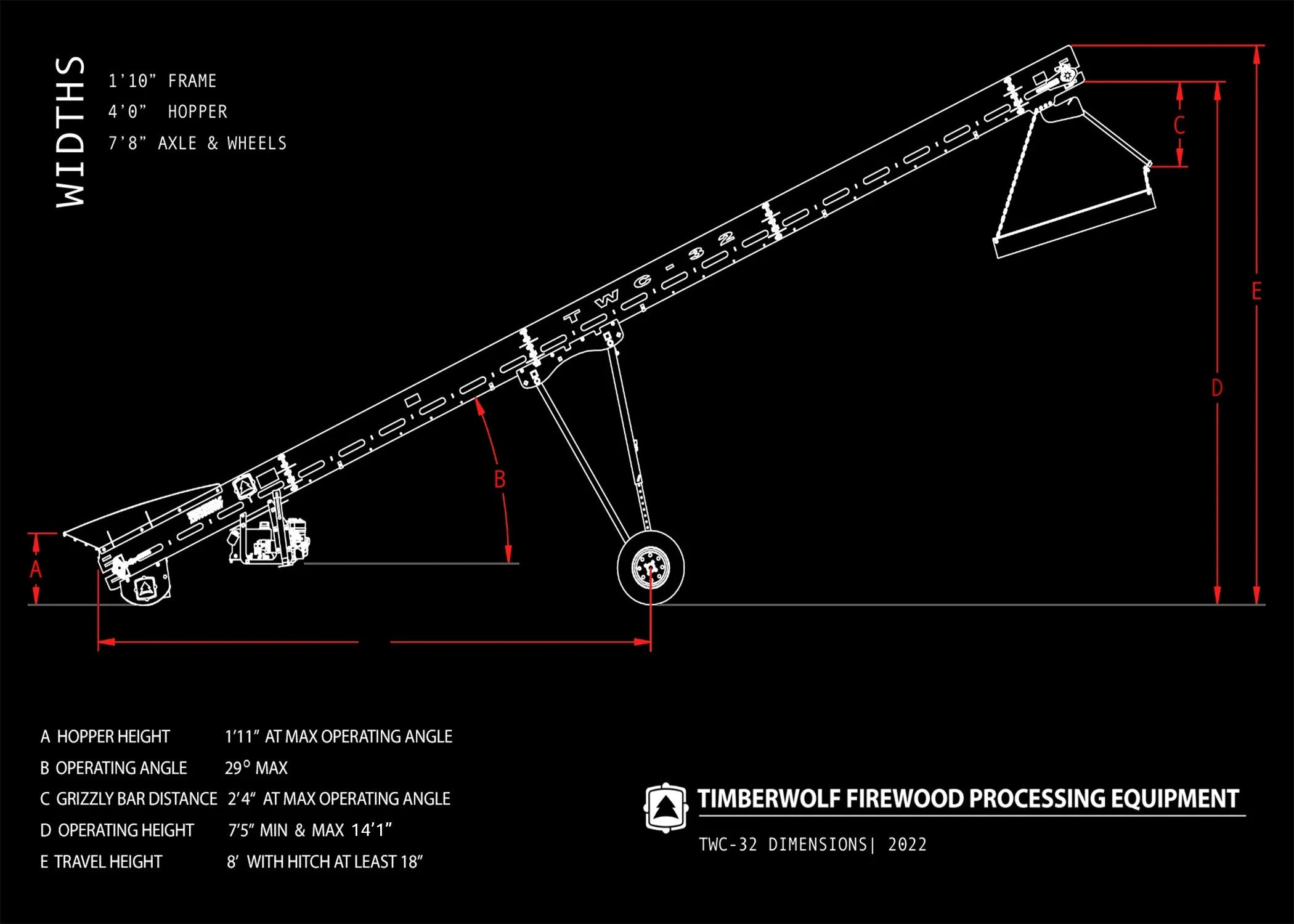

- Weighing 2,040 pounds with a frame length of 32’, the TWC-32 is our largest firewood conveyor model, perfect for large-scale commercial projects that need a boost in productivity.

- When in operation, the TWC-32 wood elevator is stabilized by a ground skid. The ground skid maintains contact with solid ground, which keeps the log conveyor sturdy while handling large loads. This results in a cleaner pile of firewood at the end of the conveyor belt and a longer product lifespan.

- The rubber belt fines deflector (located just beneath the hopper) also filters debris from falling into the roller.

- Adjusting the height of the TWC-32 conveyor is simple with our hydraulic lift cylinder. Because of the log conveyor’s size, it uses telescopic axles, which are two arms on either side of the hydraulic lift cylinder. The telescopic axles provide a sturdy base for the TWC-32, which dramatically reduces the risk of the conveyor tipping. Also, the telescopic axles can adjust height along with the hydraulic lift cylinder; simply remove the pull pins securing the telescopic axle arms to adjust the height and re-insert them once the conveyor is at your desired height.

- Because of the wood conveyor’s tapered rollers design, the belt will pull itself back towards the center if misaligned, even if the conveyor is on uneven ground.

- Logs can be fed onto the firewood elevator via the modular hopper. Constructed out of 3/16” High Steel plate steel on the bottom and 1/8” plate steel on the sides, the hopper will handle cords of firewood for years of reliable service. Not only is the modular hopper heavy-duty, but it is bolt-on, making removal and upgrades easy.

- Optionally, 36” long Grizzly Bars can be added to the TWC-32 wood conveyor. This optional add-on bolts onto the end of the conveyor and cleans out fine material from your firewood before it is offloaded.

- The wood elevator can optionally be constructed with an oscillating axle that allows the TWC-32 to move side-to-side, either via a manual adjustment or driven roller.

Stabilizing Ground Skid

The ground skid maintains contact with solid ground, which keeps the firewood elevator sturdy while handling large loads. It also lifts the roller off the ground, which provides more room for debris to fall. The TWC-32 firewood conveyor's ground skid contributes toward cleaning wood and maintaining the health of the firewood machine.

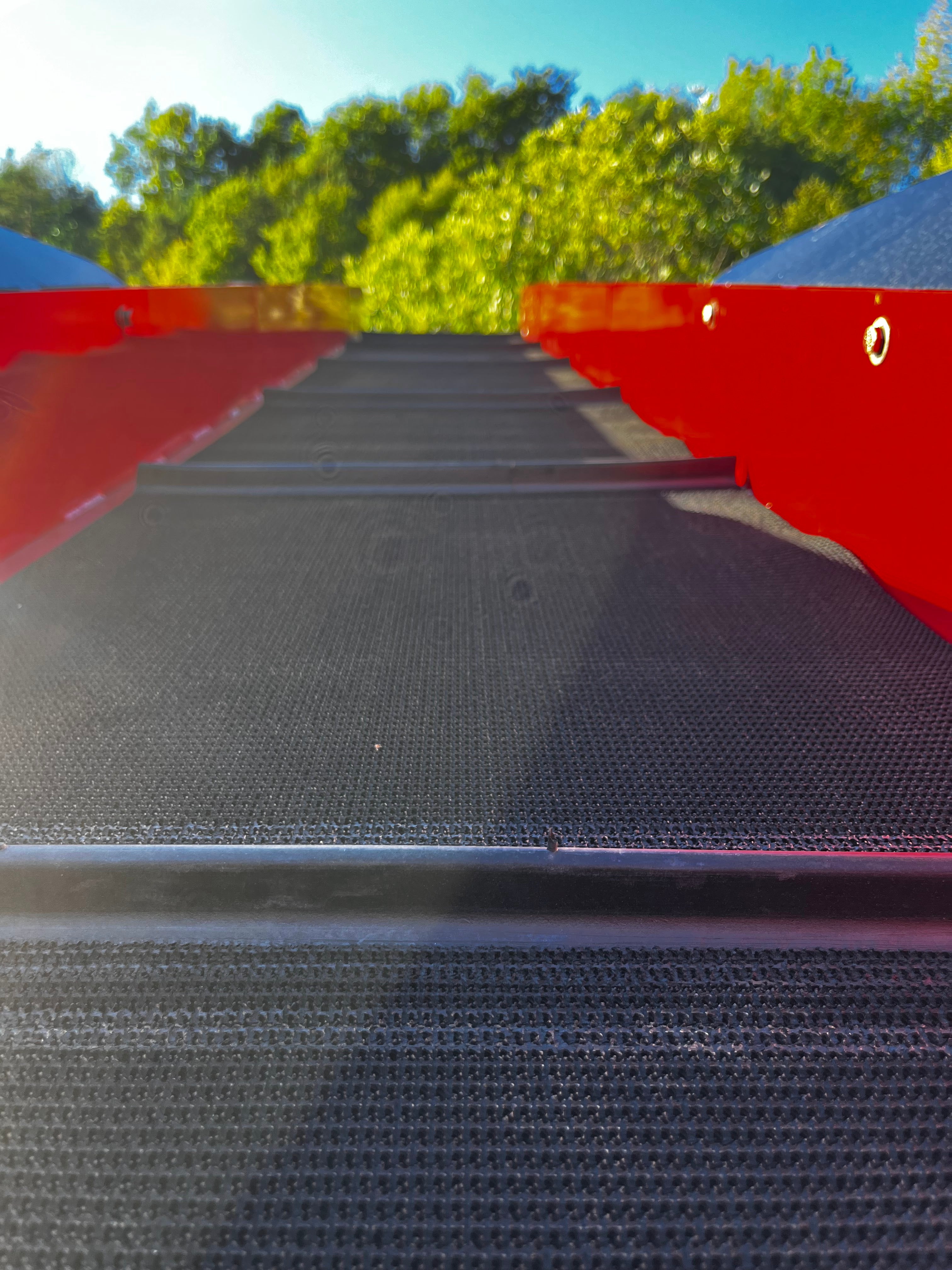

Paddle Belt Conveyor

A paddle belt is equipped to the TWC-32 wood conveyor. The paddle belt provides maximum stability for traveling logs, even in extreme weather conditions.

Always Stable, Even When 14' in the Air

All TWC firewood conveyors use a hydraulic lift cylinder to raise and lower the wood conveyor, but with larger models like the TWC-24 and TWC-32, telescopic axle arms come standard on either side of the hydraulic lift cylinder.

The axle arms are used on larger models for enhanced stability when the firewood conveyor is in operation.

When the pull pins are removed from the telescopic axle arms, they will move along with the hydraulic lift cylinder as it changes height. Once the desired height is achieved, simply re-insert the pull pins.

Make height adjustments quickly and safely with the TWC-32 wood conveyor.

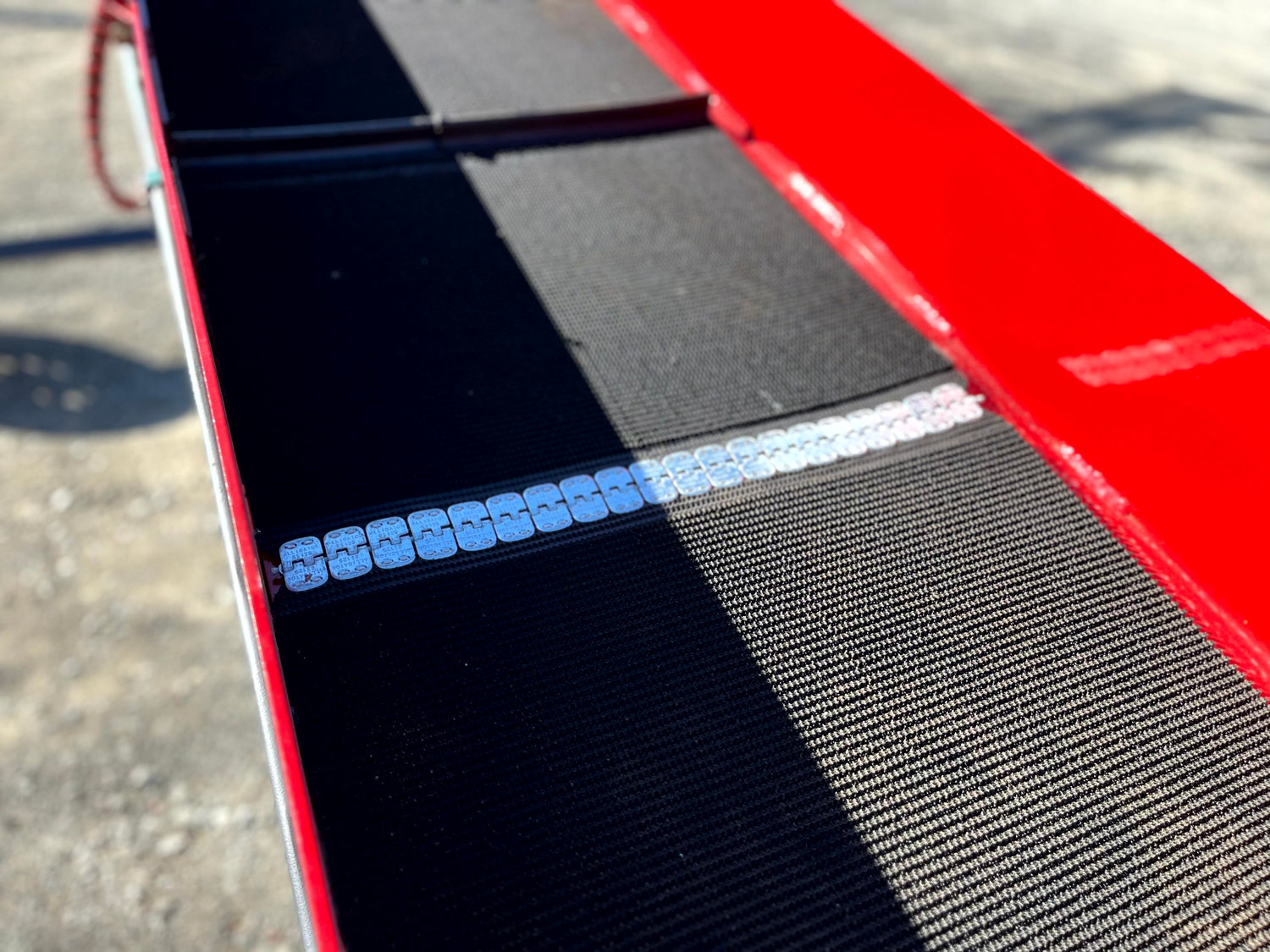

Tapered Rollers

The TWC-32 log elevator comes standard with tapered rollers. The slight inward taper on these rollers allows the belt to self-align if slightly off-center.

Why the tapered rollers? Well, we were sick of belt tracking issues, and we're guessing you are too. Luckily, having to constantly realign your conveyor belt is a thing of the past with this wood conveyor.

Clean Wood Without Any Extra Effort

Timberwolf's firewood conveyors do more than just move split logs from point A to point B. Features like the rubber belt fines deflector clean forward-moving logs, so you have a clean pile of firewood when it is offloaded.

The rubber belt fines deflector is located just beneath the hopper and prevents debris from falling into the roller and making its way into your firewood pile.

Additionally, optional Grizzly Bars can be added to the TWC-32 log conveyor. Simply attach the bolt-on frame to the end of the firewood conveyor and watch debris fall to the ground as your split logs are offloaded.

Plate Steel Constructed Modular Hopper

The modular hopper on the TWC-32 firewood conveyor makes loading logs simple, as it can be filled directly with loader buckets because of its funnel-like shape. Constructed out of High Steel plate steel, the hopper is not only heavy-duty, but it is bolt-on, making removal and upgrades easy.

Easily Movable Firewood Conveyor

Operators can easily reposition the wood conveyor to avoid large piles of firewood quickly with the TWC-32. This firewood machine uses an oscillating axle that allows for lateral movement, unlike traditional axles that only face forward.

By pushing the conveyor to either side, the machine effortlessly achieves this movement. Users can also opt to equip the machine with a drive motor that is operated via two single-spool valves.

- Choosing a selection results in a full page refresh.

- Opens in a new window.