Timberwolf Firewood Processing Equipment

Pro-HD XL

Pro-HD XL

Firewood Processor

Machine & Price includes 4-strand live deck.

Couldn't load pickup availability

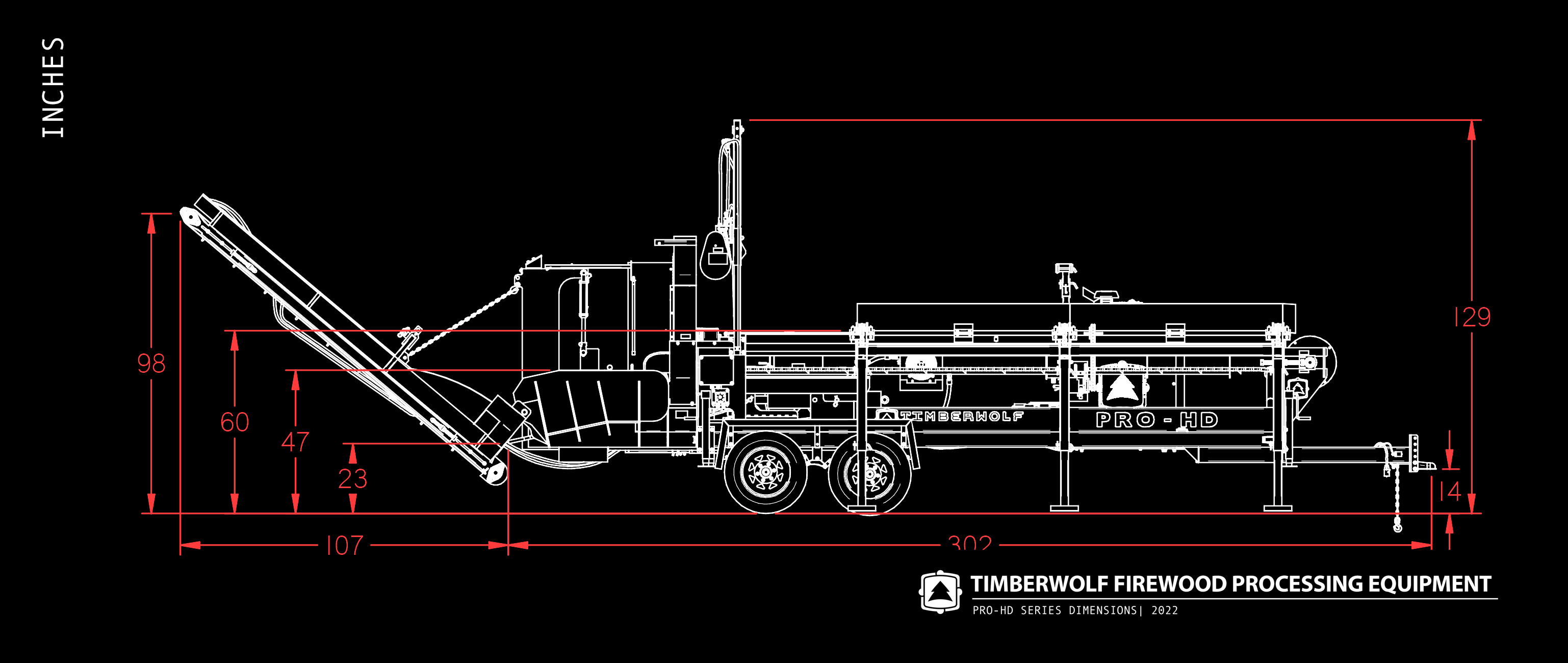

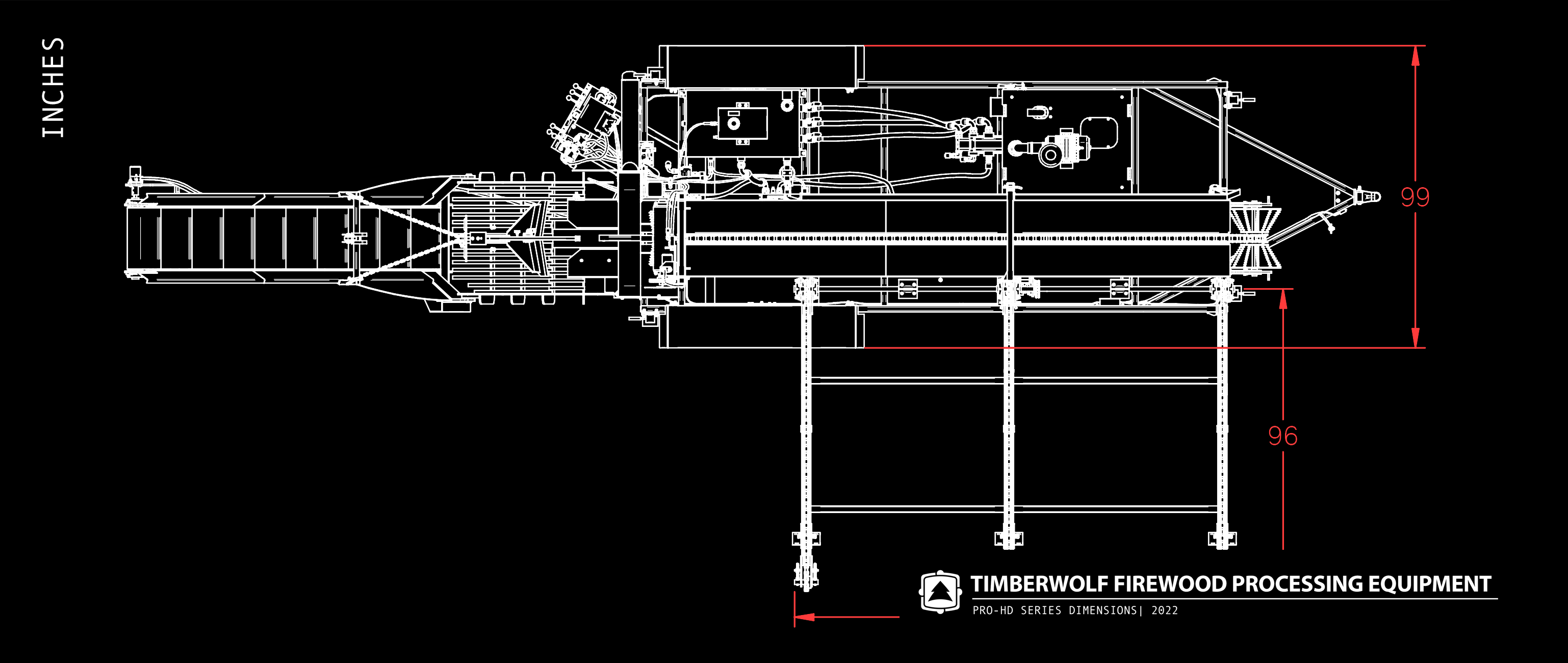

- The Pro-HD XL is a commercial firewood processor that takes the tried and true frame and features of the Pro-HD and amplifies the power and speed of the wood processor’s functions with a 74 HP Hatz diesel engine. Not only can the Pro-HD XL handle 24” diameter logs and logs longer than 32’, but it can do it with a cycle time as low as 3 seconds, which results in outputting up to 5 cords per hour.

- The Pro-HD XL industrial firewood processor is designed to handle logs larger than 32’ thanks to its hourglass-shaped back roller and Timberwolf's driven top roll clamping system. With 1,000 pounds of pressure, the driven roller clamp can handle even crooked logs. When set to "float," it applies 300 pounds of pressure, allowing for easy adjustments to ensure precise cuts every time.

- The hourglass-shaped back roller of the log processor is designed to guide logs toward the top roll clamping system. Equipped with teeth, the back roller can effectively manipulate the logs’ positioning by moving them either forward or backward for adjustments. This allows operators to feed logs longer than 32’ with the feed trough via two driven rollers, and then secure forward-moving logs with the roller clamp for clean and precise firewood processing.

- The commercial-grade firewood processor comes standard with 4-strand live deck. The live deck can support a full cord and uses driven roller chains to advance logs onto the feed trough. The live deck also offers enhanced capability for handling small and/or crooked logs, and is equipped with a hydraulic lift to make setting up simple. Additionally, the live deck can be stored in a vertical position using the stow bar for transportation.

- The Pro-HD XL is equipped with a 5” cylinder, and because of the regeneration manifold and 2:1 cylinder ratio, the fast wood processor’s push block cylinder will cycle every 3/4.5 seconds. The speed of the log processor allows operators to output 4 cords or more per hour.

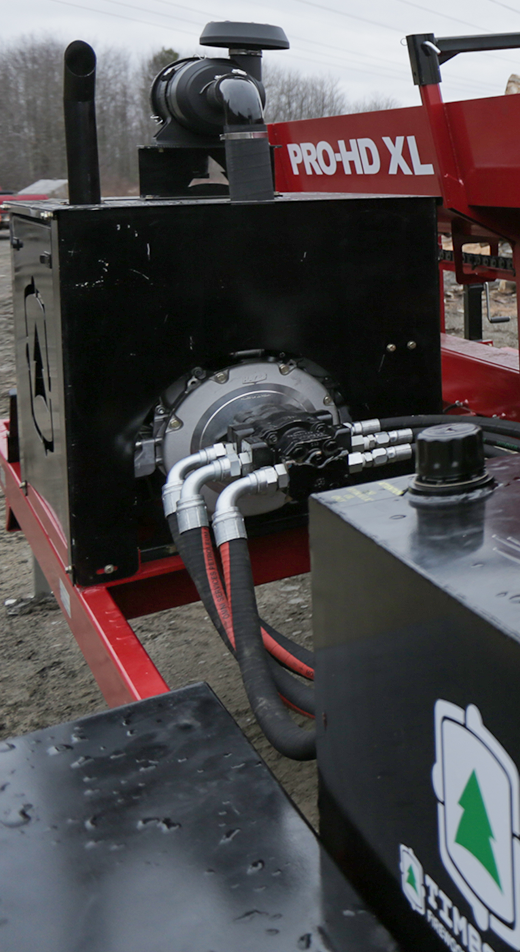

- The 74 HP log processor with a chainsaw is equipped with a high pressure gear pump, which operates in three stages to control various functions. Each stage has a different pump flow rate, enabling faster and more powerful simultaneous operations throughout the machine.

- Our firewood splitting wedges are made from AR400 steel, known for their durability and resistance to wear and abrasion. Whether you choose our 4-Way, 6-Way, 8-Way, or 12-Way Wedge, these firewood processing knives will retain their splitting performance, maintaining the same quality as during their first split even after 10,000 splits.

Newly Improved Cut Time

Timberwolf's Pro-HD Series Firewood Processors now feature a Bent Axis Piston Saw Motor. Our engineers worked to customize the internals of the motor, making it the perfect addition to our updated Pro-HD Series frame. The Pro-HD now uses a Gem Bar and Sprocket, which is thicker than our previous bar, for increased performance and longevity.

With a saw speed of 8,700 fpm, this robust and reliable hydraulic motor dramatically improves the performance of the commercial firewood processor, cutting three times as fast as older Pro-HD Series models.

The highly efficient saw motor allows operators to cut logs up to 24" in diameter in just 5.5 seconds, resulting in an average cord output of 5+ cords per hour.

Innovative Firewood Machinery

Our patented top roll clamping system allows operators to process 32' long logs through a 16' long feed trough.

The driven top roll clamping system applies 1,000 pounds of downward pressure on logs being processed, which is enough pressure to leave a few feet of the log hanging off the back roller with full security.

No more cutting down logs before processing them, just get right down to business.

Enhanced Traction on Forward-Moving Logs

The Pro-HD XL processor's hourglass-shaped back roller feeds logs toward the top roll clamping system. The back roller's teeth engage logs and can move them forward or backward for adjustments, so operators can position forward-moving logs with the top roll clamping system for a clean and quick cut.

Pump Flows For Performance

A 3-stage high pressure gear pump controls various functions of the firewood processor with a chainsaw. The first stage has a pump flow of 33 GPM and powers the splitter. The second stage has a pump flow of 22 GPM and powers the saw. The third stage controls the auxiliary functions of the Pro-HD XL wood processor, such as the conveyor, live deck, and feed trough, with a pump flow of 14 GPM. These flow rates allow for faster and more powerful operations, from the feed trough to the power saw.

74 HP Diesel Engine

The most powerful of our firewood processor models, the Pro-HD XL runs on a 74 HP Hatz diesel engine. This engine allows for longer run times, which means more production. It drives a 33GPM splitting pump and provides 3,000 PSI of splitting pressure.

Large Hydraulic Tank

Along with a 74HP engine, the Pro-HD XL firewood processor has a 70-gallon hydraulic tank. These features combined, allow for maximum power and fast cycle times. The size of the hydraulic tank and filler breather ensures that the contained fluid is cooled and filtered with each stroke, also equipped with internal baffles to eliminate vortices.

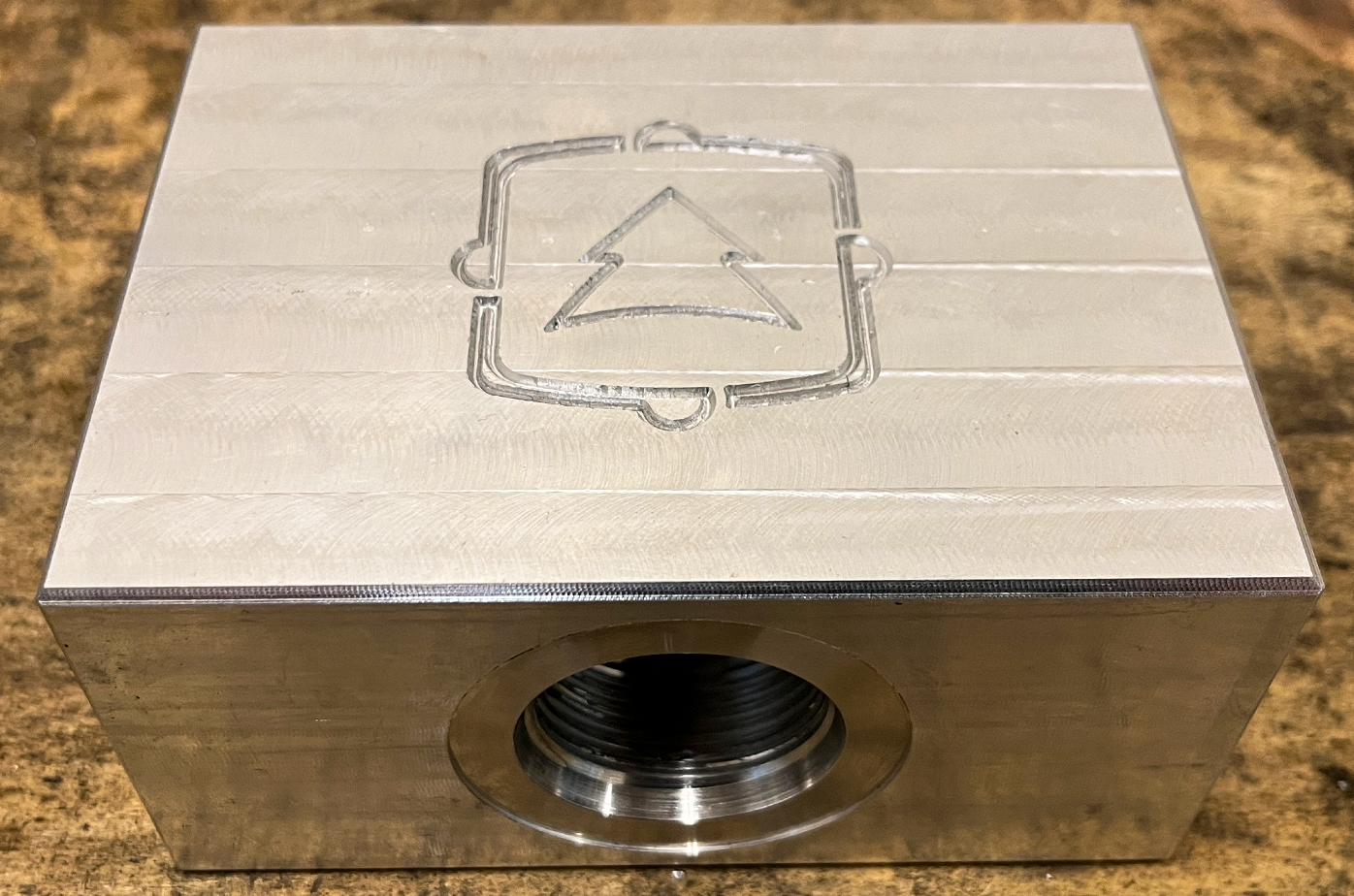

Regeneration Manifold Speed

Featured on the Pro-HD XL firewood processor: the Timberwolf regeneration manifold. The regen manifold drives a regeneration cycle when hydraulics move through the valve. A regeneration cycle is used to decrease the time it takes to extend the rod from the cylinder until it hits the workpiece. This allows a cylinder to be extended more rapidly while using the same pump flow.

This manifold creates fast cycle times on the wood processor without using more energy, allowing for higher cord per hour output with less operator time spent.

4-Strand Live Deck

The Pro-HD XL firewood processors for sale come standard with a 4-stand live deck that better handles small and/or crooked logs because of the additional surface area that can support logs that may fall off.

The live deck is moved easily via a hydraulic lift, allowing for simple setup at the jobsite, and can be stored and secured vertically for transportation. Fully DOT certified and road legal, these machines were designed with mobility in mind. Drive at highway speed with comfort. Ample ground clearance to get into the nastiest of landings. Deploy in minutes to maximize processing times.

Time-Saving Hydraulic Wedge Lift

With the Pro-HD XL's hydraulic wedge lift operators can raise and lower the firewood processor wedge from the operator's panel. This Pro-HD XL firewood processor function eliminates the need for operators to manually change the wedge height or change out the wedge altogether.

Just size up your block and watch your firewood wedge of choice split the log into uniformly sized firewood. Then do it all again, no matter the size of your block.

AR400 Steel Constructed Wedges

All of our firewood splitting wedges are constructed from AR400 steel, which is designed for abrasion and wear resistance. Our 4-Way, 6-Way, 8-Way, and 12-Way Wedges will still be splitting with the quality of the first split on their 10,000th split.

Hoses That Handle Everything and More

All Timberwolf firewood processors use industrial-grade hoses to route the flow of hydraulic functions. We use heavy-duty hoses because of their rugged construction, abrasion and kink resistance, and, most importantly, their ability to withstand high-pressure fluids.

Customer safety is a top priority for us, so we use the highest quality materials to ensure your safety.

- Choosing a selection results in a full page refresh.

- Opens in a new window.