Timberwolf Firewood Processing Equipment

Pro-MP

Pro-MP

Firewood Processor

Machine & Price includes 4-Way Wedge.

Couldn't load pickup availability

- As a firewood seller, you are constantly trying to improve productivity, but productivity often comes with a price tag that just doesn’t make sense for most companies/individuals. The solution? The Pro-MP, a full-frame processor for $40,000 that will effectively cut and split logs as wide as 24” in diameter and in excess of 32’ in length.

- You may not always work with large logs, but perfect processing logs will not always be available, and you don’t want to deal with the hassle of loading a log on your small wood processor just to find out your it can’t handle the log.

- With other firewood processor manufacturers, you’ll have to spend at least the cost of two Pro-MPs for the ability to process 24” diameter logs and logs as long as 32’. Compared to the Pro-MP portable firewood processor, which starts at $40,000 and can be customized with add-ons, the decision is simple. Save your money and boost your productivity.

- The mid-sized firewood processor can process logs in excess of 32’ because of the machine’s hourglass-shaped back roller in combination with Timberwolf’s patented driven top roll clamping system. The driven roller applies 1,000 pounds of downward pressure on forward-moving logs to handle any crooked logs. When in “float,” the roller clamp will apply 300 pounds of pressure on logs so you can make simple back-and-forth adjustments for perfect cuts with the hydraulic saw each time.

- The 22 HP mid-sized wood processor comes standard with a 6’ long by 12’ wide 3-strand live deck with a hydraulic lift. Up to 2 face cords can rest on the live deck. Driven roller chains move logs onto a 16’ long feed trough. For transportation, the live deck can be stored vertically and secured via a stow bar.

- The feed trough features two driven trough rollers and the previously mentioned top roll clamp. These driven rollers make for easy and precise log adjustments on the feed trough.

- This $40,000 log processor can output 2 full cords per hour. With a commercial-level output at half of the price, the Pro-MP is the best firewood processor for the money.

- Firewood processors are often a pain to get set up in the right location, so once they are set up, they usually stay there. This isn't a big issue until you are wasting miles on your logging truck just getting logs to the processor. With this portable wood processor, this is an issue of the past. The heavy-duty firewood processor weighs in at 5,500 pounds and is easily towable by any half-ton truck.

- The Pro-MP wood processor runs on a 22 HP GX700 Honda engine. A 22 GPM Anfield gear pump powers the machine's hydraulics. The pump drives a 4" or 5" cylinder, resulting in a 5-second cycle time with the 4" cylinder and a 7-second cycle time with the 5" cylinder. A large 30-gallon thermodynamically efficient hydraulic tank ensures cool operating conditions that extend the life of the firewood log processor's hydraulic components.

- A 4-Way or 6-Way Wedge can be equipped to the mobile firewood processor. The hydraulic wedge lift in combination with the design of the Pro-MP allows easy access to the splitting chamber for re-splits.

You CAN Afford a Pro-MP!

Available Inventory

Ready to bring home your own Pro-MP? Machines are in stock at Timberwolf Certified Dealers across North America.

Find a Dealer

Easily Handle 24" Wide Logs

With competitors, it will cost you upwards of $80,000 just for a wood processor that can process a 24” wide log - and just because these machines can, it doesn’t mean they should.

The Pro-MP mobile wood processor has a frame more than capable of processing large logs. Also, the frame of the mid-sized log processor is designed for accessibility, making adjustments not only easy but safe.

Process a Tree for $40,000

With the Pro-MP firewood processor's back roller, it's now possible to handle 32-foot-long logs. An hourglass-shaped roller with large teeth is located at the end of the machine, enhancing the traction of forward-moving logs. This feature reduces operator intervention and results in easy firewood processing.

3-Strand Hydraulic Live Deck

The Pro-MP has a 6' long by 12' wide 3-stand live deck with a full roller chain, idler, and driven sprockets, so it can guide monster logs onto the 16’ long feed trough with ease. Approximately 2 face cords can rest on the live deck of the mid-sized firewood processor.

The live deck can be raised and lowered using a hydraulic lift cylinder, as well as stored for transportation using the stow bar.

Process Long Logs Quickly

Standard on all Timberwolf firewood processors, the driven top roll clamp is featured on the Pro-MP. The driven top roll clamping system applies 1,000 pounds of downward pressure on forward-moving logs, which secures the logs and reduces the need for the saw to re-engage the log after the initial contact.

An hourglass-shaped roller with large teeth is located at the end of the machine, enhancing the traction of forward-moving logs. This feature reduces operator intervention and results in easy firewood processing.

Simple and Safe Operation

The Pro-MP log processor uses manual valves to control its functions. These manual valves lend themselves to the safe operation of the wood processor. Furthermore, the mobile wood processor was designed to be highly accessible - from the feed trough to the splitting chamber - to make re-splits and adjustments simple and risk-free. Output 2 cords per hour with this full-frame wood processor.

The Ultimate Mobile Firewood Processor

Yes, most firewood processors on the market have a ball hitch coupler, but that doesn't necessarily make them easy to move around; they are heavy, large, and ultimately, a hassle.

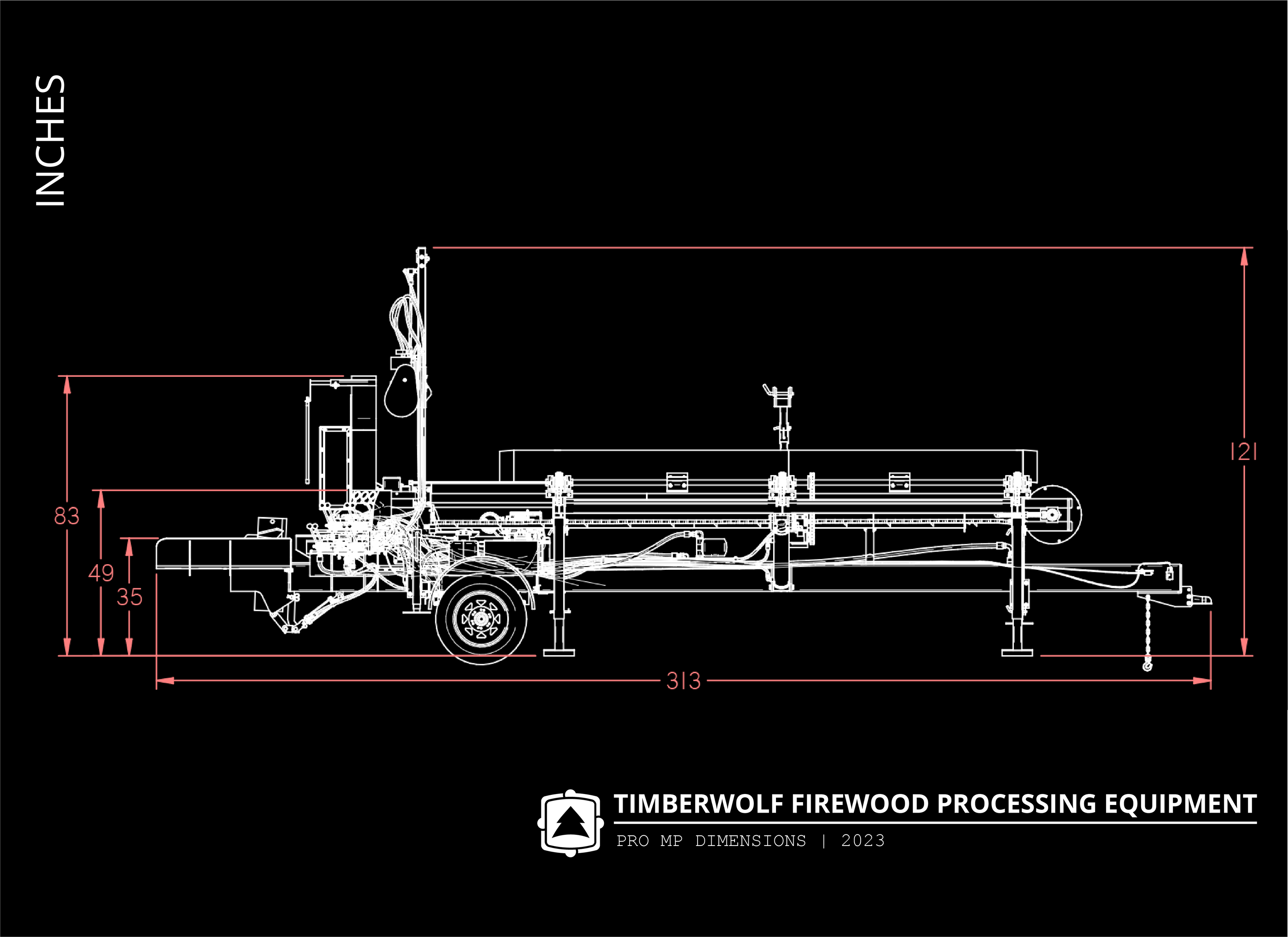

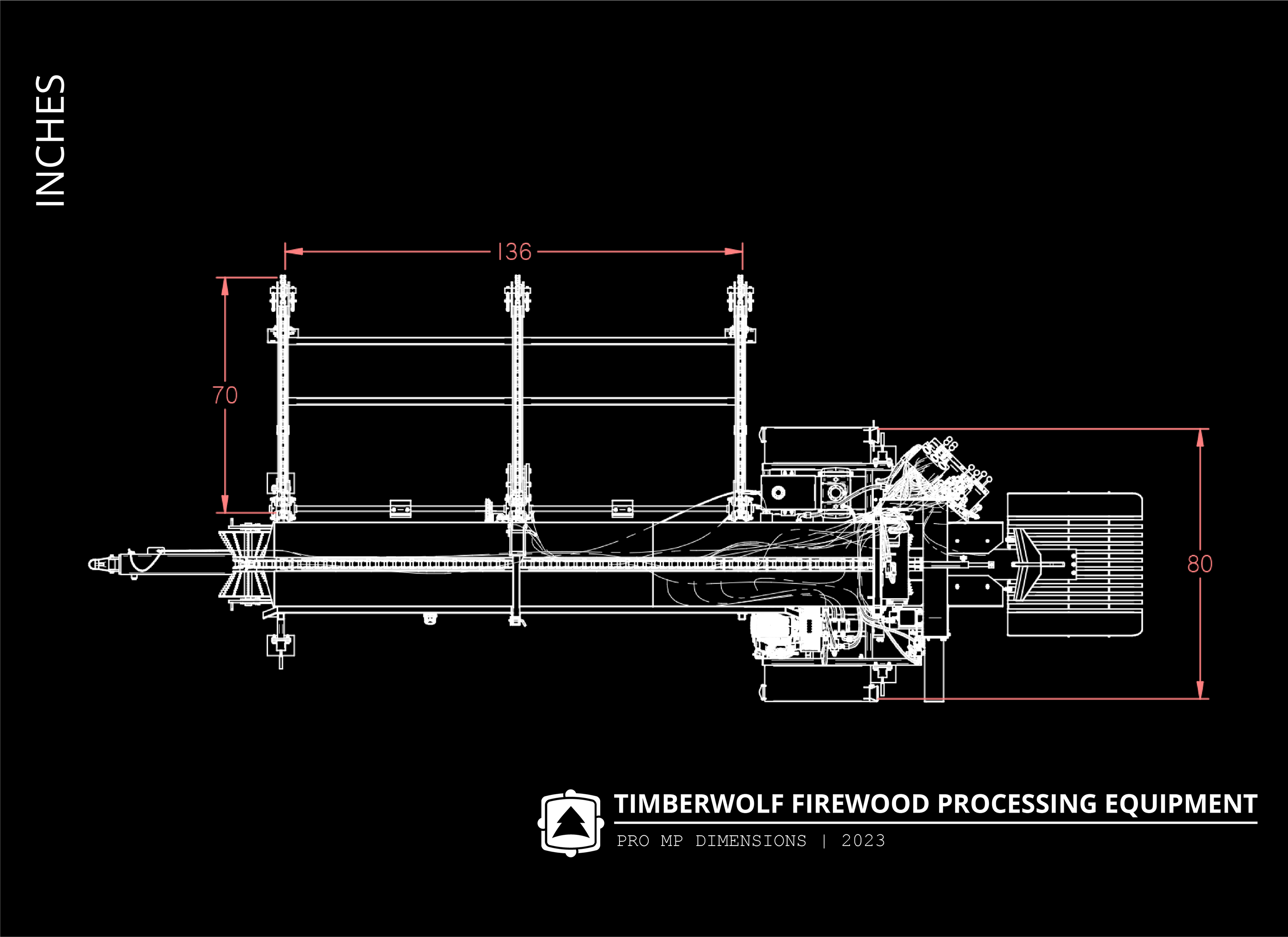

Transporting the Pro-MP is simple, as it has small dimensions and a weight of only 5,500 pounds. Any half-ton truck can move the towable firewood processor from one spot to another, or even miles down the road.

Easy Wedge Adjustments

With the Pro-MP firewood processor's hydraulic wedge lift operators can raise and lower their 4 or 6-Way Wedge from the operator's panel. This function eliminates the need for operators to manually change the wedge height or change out the wedge altogether.

Plus, operators can move the wedge out of the way when reaching into the splitting chamber in order to handle logs.

Cylinder Options for All Operations

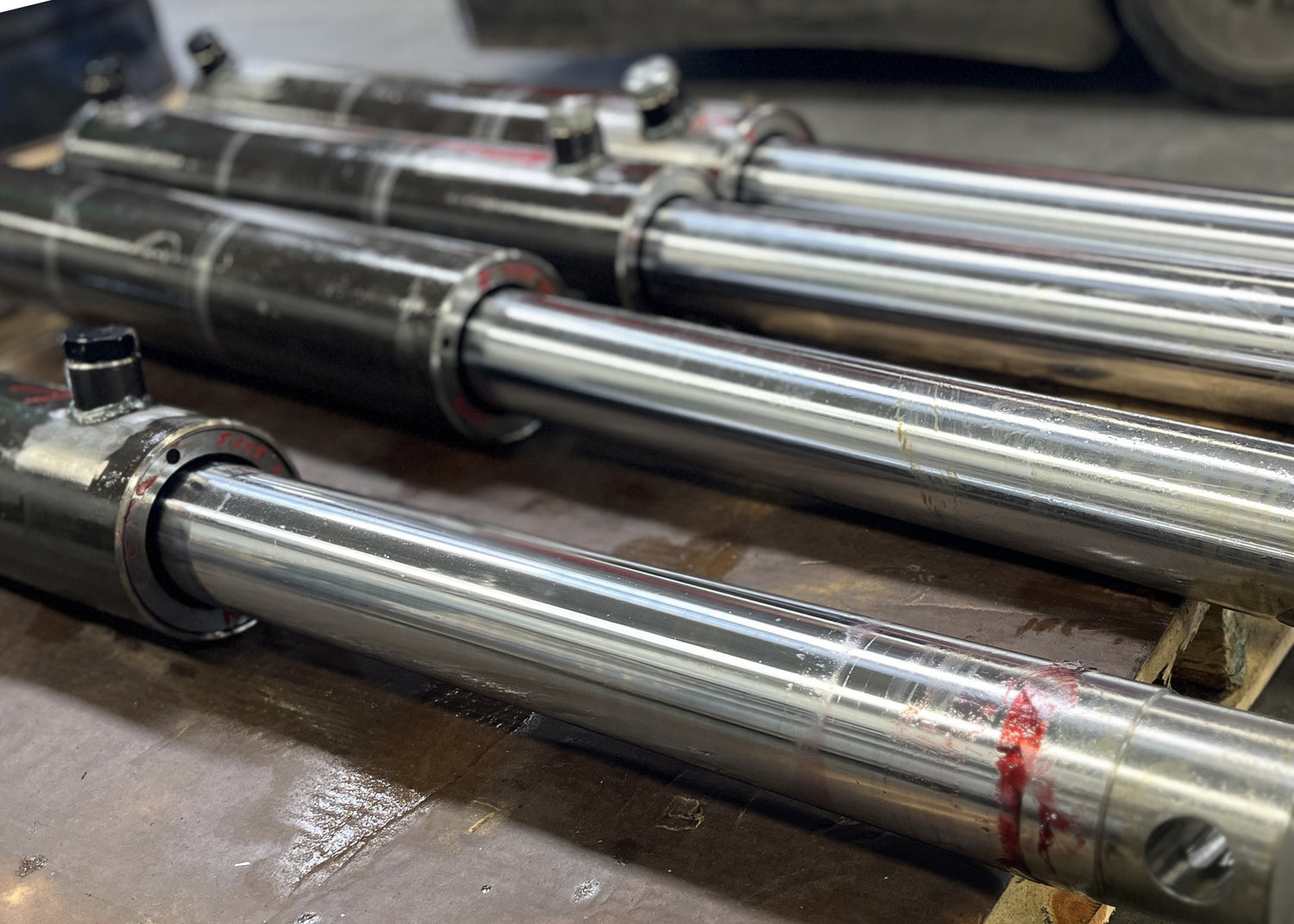

A 22 GPM Anfield gear pump drives either a 4" or 5" cylinder that pushes cut logs through a 4-Way or 6-Way Wedge. The 4" cylinder has a 5-second cycle time and the 5" cylinder has a 7-second cycle time, but the 5" cylinder offers a greater splitting force.

So, if you plan on splitting smaller logs, the 4" cylinder will handle them and do so quickly, but operators planning to split gnarly logs may prefer the 5" cylinder.

Healthy Hydraulics for Years to Come

Hydraulic fluid drives powerful splitting forces, but it can also cause breaks in production when overheated, and disrupt splitting when not filtered properly.

The Pro-MP mid-sized firewood processor has an oversized 30-gallon thermodynamically efficient hydraulic tank that ensures cool operating conditions, therefore extending the life of the mobile processor's hydraulic components.

Heavy-Duty Hoses

All Timberwolf firewood machines use Continental hoses to route the flow of hydraulic functions. We use Continental hoses because of their heavy-duty rubber construction, abrasion and kink resistance, and, most importantly, their ability to withstand high-pressure fluids.

Customer safety is a top priority for us, so we use the highest quality materials to ensure your safety.